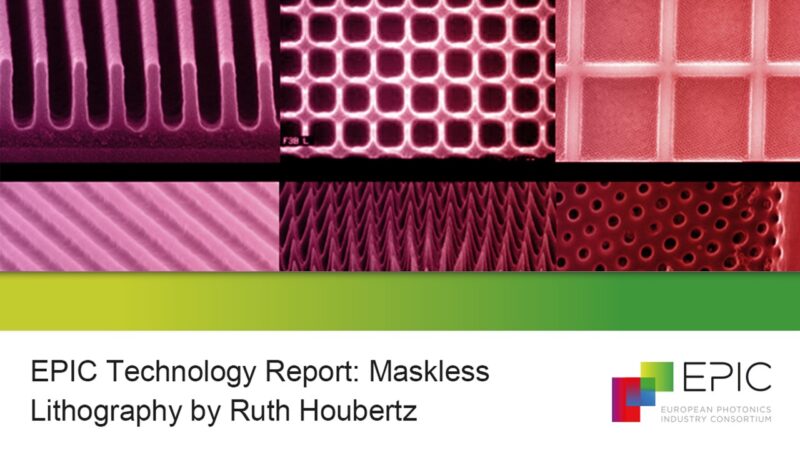

EPIC Technology Report: Maskless Lithography by Ruth Houbertz

Key technologies of the 21st century require manufacturing processes that meet the ever-increasing demand for miniaturized, cost-efficient and easy-to-integrate components and reliable processes. Maskless Lithography technologies making use of digital manufacturing provide unique patterning capabilities with extraordinary high levels of degrees of freedom, continuously advancing the current state of the art. Their implementation is driven by the continuous miniaturization of components and devices along with a demand for an enhanced functionality and performance of products.

Digital manufacturing is one of the tools to meet the needs of the different markets such as automotive, computing, sensors, medical, integrated photonics, mobile, XR, displays, light sources and detectors, illumination, and imaging. It enables a high degree of automation and a further reduction in process costs, which is required for almost all products. Maskless lithography allows either to fabricate individual structures or masters and tools which enable scaling to volume production.

Market Reports

Market Reports (2) - 3 - display